0

0

The MBBR process is based on a specially designed plastic, neutrally buoyant carrier media with a high specific surface area for biofilm attachment and growth; a design proven with over 30 years of use.

The iQ.MBBR™ process specifically includes 2 sequential treatment phases: the Fluidized Bed phase during aeration for oxygen supply, mixing, and biofilm / sludge control; and the Floating Bed Filter phase for adsorption of contaminants, biofilm growth, and simultaneous nitrification / denitrification.

Applying the non-aerated phase differs from traditional MBBR processes and results in significant energy and performance benefit. This is further enhanced by the use of dissolved oxygen (DO) sensors / control which only provides aeration when needed.

iQ.CONTROLS™ – PANEL is a custom-built panel. Each output comes in a modular design to allow three-Phase, Single-Phase loads of 10A or 20A. Choose which mode you want your output to operate in Time Dose, Demand Dose, Aeration, Chemical, Day/Night Settings or Permanently On. Duplex and Triplex setups are optional for all outputs.

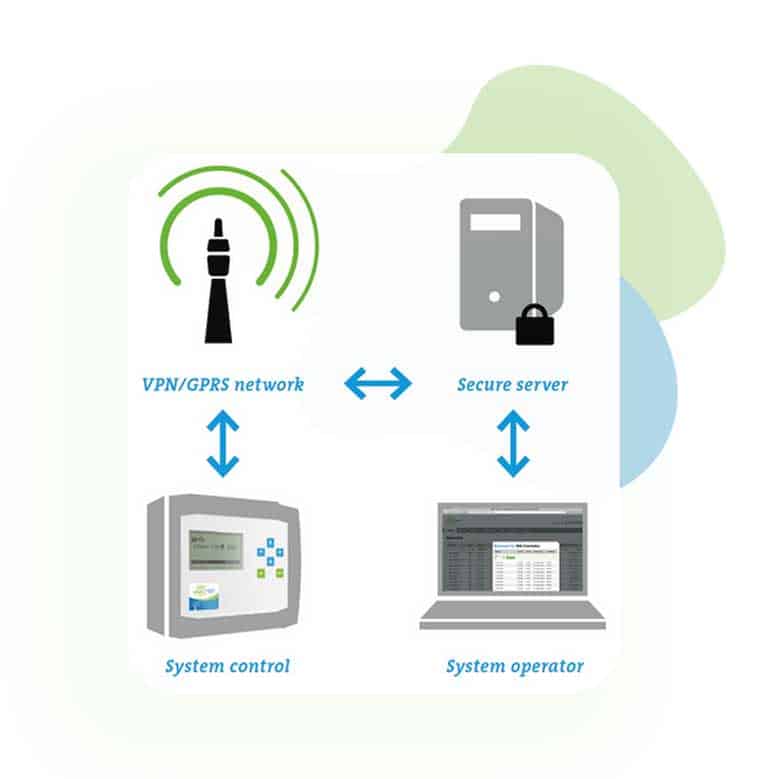

click+clean®-WEB is a web-based secure monitoring system specifically designed to provide full operational surveillance of each system with instant notification sent via email and SMS. The information is stored on a web based database providing a historical report on each system.

click+clean®-APP allows complete remote control from the service provider to remotely have access and change settings. The new click+clean®-APP enables the technicians to use all benefits onsite including the possibility to connect to back office support by video conference.

There are more than 30,000 click+clean® control panels in 27 countries. Approx. 8,000 panels are remotely managed systems.

Tanks-A-Lot is a manufacturer and distributor of iQ.MBBR™ Wastewater Treatment Plants, scalable systems capable of treating up to 100,000 gallons per day.

Residential Sewage Treatment (WSB® Brochure)

Unlike a septic tank or a sewage holding tank, your wastewater treatment plant doesn’t require routine maintenance and emptying. The unpleasant and inevitable suction removal of waste is no longer a concern! Once we install your precast concrete tanks in the ground and set up the necessary mechanics, you no longer need to dedicate time and energy towards your household waste. For a family household, you have enough to worry about without having to plan your scheduled septic tank maintenance. Free up your life with Alberta’s wastewater treatment plant that’s the right size for your family.

Commercial Sewage Treatment (WSB® Commercial Brochure)

Where there is a community of people there is the need for a wastewater management plant. If your rural residences and country communities don’t have access to municipal services then consider installing a complete treatment plant. Often times this is an effective way for a developing community to earn further support from municipal services. No matter what facility you need and whatever capacity requirement you have we can support your situation. Attempting to clean and empty a sewage holding take or even a septic tank for these situations can be costly, unpleasant, and time consuming.