Claresholm

Problem

The town of Claresholm wanted to install two additional lift stations to service a new planned 50 home and commercial subdivision. The consultant initially considered a 2400mm diameter fiberglass lift structure which presented a number of challenges. For one, the area in question had unusually high water tables which presented some buoyancy challenges. In addition, using a fiberglass product complicated site dynamics and soils management. A bigger excavation would be required and structured materials would have to be hauled in for back fill. In addition, the excavated soils would have to be hauled away for disposal elsewhere which would negatively impact the overall installed cost.

TAL Solution

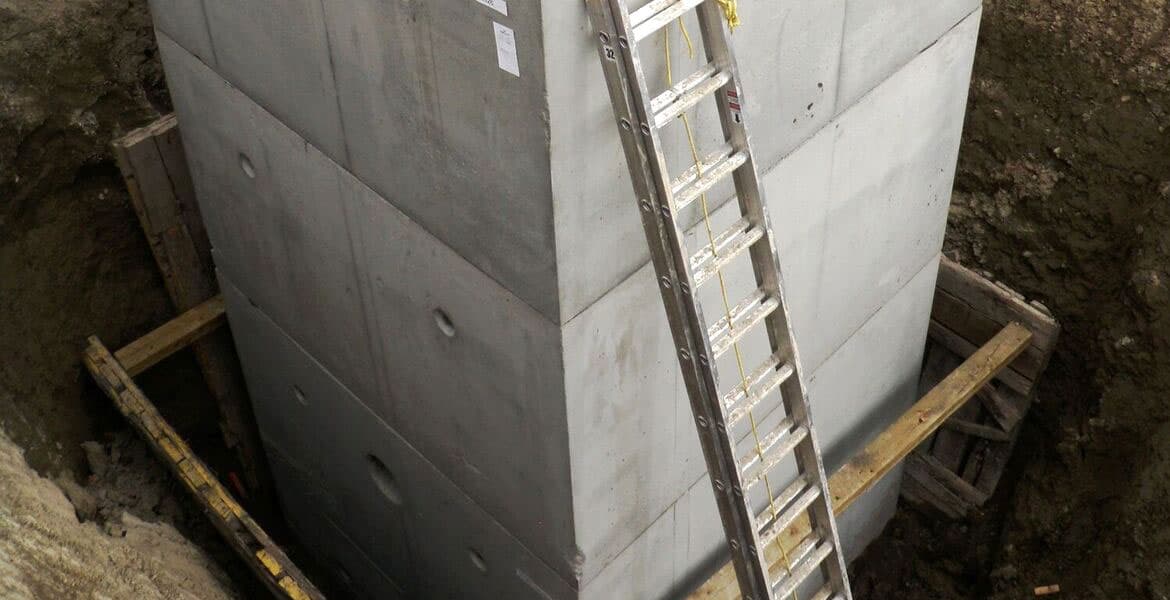

Our solution was a 2.4m x 2.4m diameter x 6.4m height square precast concrete lift station which kept the same design guidelines as the fiberglass product that had been originally specified. Going this route eliminated concerns of buoyancy as the weight of the concrete castings alone was enough to overcome any buoyancy issues. Our precast concrete solution also improved the site dynamics and soils management concerns as all the excavated materials remained on site and were used for back fill, eliminating the need to haul those materials away and to haul in engineered materials for back fill. All this meant that the overall installation cost of the project was lower by at least 30 – 40% over the fiberglass product.

Construction

It took a total of 5 weeks from the time we fabricated the first piece to the time the project was complete. Onsite assembly of the lift station took less than 6 hours.